Last week I attended the Silage for Beef Cattle Conference in Mead, NE. For those of you who put up corn silage, or provide advice for those who do I would highly recommend listening to the online uploads from this conference as well as looking over the proceedings. Here are 8 key concepts I took away from the conference:

- Processing is crucial.

Processing of the grain is very important to the digestibility and therefore, energy availability of the corn silage. It is recommended that there should not be a single intact corn kernel in the final silage product. To monitor this, separate the forage portion of the silage from the grain and then closely inspect the grain. Adequate and consistent monitoring through the chopping process is key.

- Determining when to harvest is difficult and varies by operation.

As the plant matures fiber increases, kernel hardness increases thereby decreasing the digestibility of the forage and starch portions of the plant. However, at a more immature stage less corn kernels are present, and the moisture of the plant is too high for ensiling. Therefore, the recommendation was to harvest a week before or at black layer when the dry matter content of the green chop is between 33 – 38%. However, the best practices may differ from operation to operation.

- Ensiling time is important.

As fermentation time increases, starch digestibility also increases. For the fermentation to go to completion, it is recommended to ensile at least 90 days, but 120 days would be optimal.

- Packing is key to minimize shrink and prevent spoilage.

Delayed packing increases risk of yeast and mold spoilage. It is also important to pack with enough weight and consistency. Check out this packing density calculator from University of Wisconsin extension.

- Proper covering is also key to prevent shrink and spoilage.

O2 barrier plastics are the best option for covering, however polyethylene coverings are also an option with about a 5% difference in dry matter recovery.

- There are lots of ways ensiling can go wrong.

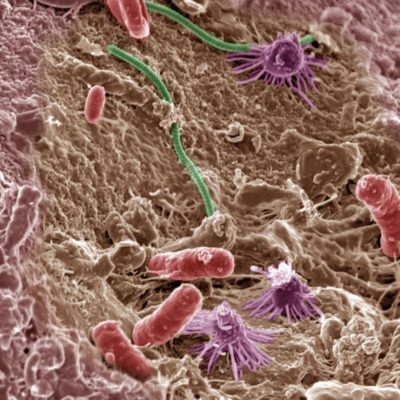

Silage contaminants can come from many different sources including soil, damages plants from hail or insects, manure, wildlife, rodents and birds. These contaminants can include infectious microorganism such as salmonella, listeria, clostridia and toxin producing molds or undesirable fermentation by-products such as toxic amines or ammonia.

- Feeding spoiled corn silage at any inclusion rate is detrimental to rumen health.

Both dry matter intake and digestibility of neutral detergent fiber decrease when spoiled corn silage is included in the diet. Additionally, when cannulated cattle were examined, the forage mat in the rumen was completely destroyed, again at any inclusion rate of spoiled corn silage.

- Producers can determine if they have aerobic deterioration of silage on farm.

At Ward Laboratories, Inc, I often suggest producers who are unsure of their silage to test both mold count and pH. On farm producers can take the temperature of the center of the pile and other outer locations. Moldy spots will be 20-30°F hotter, with up to 8 times the coliform forming units of mold than the core of the pile.

Again, this is a snapshot of the important information shared at the corn silage conference. Check out the online uploads and consider sending your silage samples to Ward Laboratories Inc. to test for nutrient contents, pH, moisture and mold count.

[…] most corn crops are too dry to meet the guideline of between 33-38% dry matter as covered at the Silage for Beef Cattle 2018 Conference. A lot of the green chop sample that have been analyzed here at Ward Laboratories, Inc. in the […]

[…] most corn crops are too dry to meet the guideline of between 33-38% dry matter as covered at the Silage for Beef Cattle 2018 Conference. A lot of the green chop sample that have been analyzed here at Ward Laboratories, Inc. in the […]

[…] making silage, follow proper procedures and best practices for ensiling to preserve that […]