Ethanol co-products have been abundantly available to be utilized as both a energy and protein source since the mid-2000s. However, using by-products of distillation as animal feed is not a novel concept. In the 1800s, beverage distilleries began feeding spent grains to livestock due to environmental regulations prohibiting the dumping of “waste by-products” into nearby streams and rivers. In 1945, Seagrams, Walker & Sons Distillers Corporation decided to host an industry meeting including university experts and government officials. Thus, the Distillers Feed Research Council was founded, and is known today as the Distillers Grains Technology Council.

Fast forward to the early 2000s, when ethanol production from corn became common practice for the production of renewable fuels, E85, E15 and E10. Suddenly, there was an abundance of ethanol by-products available at low cost for livestock feed. Initially, ethanol producers viewed these by-products as waste. More recently however, ethanol producers view these by-products not as waste, but as co-products of production. The ethanol industry has invested both time and money into fractionation of these products to better meet animal nutrient requirements.

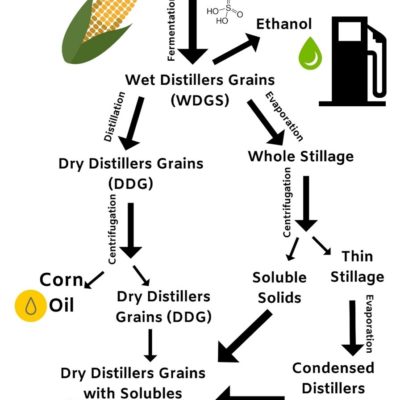

Last week, I attended the 23rd Distillers Grains Symposium. I learned about the nutritional value of ethanol co-products and where each product originates from in the dry milling or wet milling process.

Nutritional Value of Distillers Co-Products

The nutrient composition of distillers grains is roughly concentrated to be 3 times that of corn grain on a dry basis because approximately 2/3 of the corn grain is starch. In livestock diets distillers grains can be used to provide both protein and energy.

The average protein content on a dry basis is 30%, the average Total Digestible Nutrients (TDN) on a dry basis is 98% and the average Metabolize Energy (ME) on a dry basis is highly variable with fat content. As a protein supplement, ethanol co-products provide ruminally undegradable protein (RUP) or by pass protein at approximately 70% of crude protein. Due to the high levels of bypass protein in distillers grains it is important to use the metabolizable protein model, which incorporates both RUP and ruminally degradable protein (RDP), when balancing a ration to achieve optimal cattle performance. In swine diets, it is important to remember that lysine is the first limiting amino acid as it is a corn based product.

As a source of energy, trials have shown wet, dry and modified distillers have a TDN of between 115% – 130% that of corn grain in forage and concentrate ruminant diets respectively. In swine and poultry, energy content is highly dependent on fat levels.

Distillers grains and co-products also contain minerals and vitamins important for animal nutrition. In fact, one advantage distillers grains have over corn for swine diets is more available phosphorous. In corn, approximately 40% of total phosphorous is bound as phytate. After the fermentation process, the available phosphorous increases to 50-70% of total phosphorous in distillers grains. Additionally, due to the presence of the yeast, ethanol co-products are also a good source of bio-available vitamins.

Dry Milling Processing Plant Ethanol Co-Products

Wet Distillers Grains with Solubles or Wet Cake (WDGS)

The removal of starch from the corn grain results in WDGS.

Partial drying of WDGS results in Modified Distillers Grains with Solubles (MDGS).

Dry Distillers Grains (DDG)

Distillation of WDGS results in two products: whole stillage and DDG. After this drying process, the DDG is slightly lower in energy due to the absence of the solubles.

Corn Oil

The fat portion of corn is removed from distillers grains. Before removal, fat composition of distillers grains is 9-14% on a dry basis. After fat removal, fat composition of distillers grains is 2-6% on a dry basis. Ethanol plants can sell the corn oil as a separate product, and deoiled distillers grains can have a higher inclusion rate in the dairy and beef diet without detrimental effects of fat on milk fat and rumen gut health. Ruminant nutritionist typically keep the fat below 7% of the total diet on a dry basis.

Soluble Solids

This portion of the feed is separated from the thin stillage by centrifugation. Many vitamins and minerals from the corn and yeast are contained in the soluble portion of the feed. This portion can either be added back to the DDG or marketed as a separate feed product.

Condensed Distillers Solubles or Syrup (CDS)

The syrup or CDS is the result of evaporation of thin stillage, removing the majority of the water content. Although it is a liquid feed, the syrup is 80 – 90% dry matter.

Dry Distillers Grains Solubles

This is the most common ethanol co-product fed to livestock. It consists of the dried distillers grains with the soluble solids and sometimes syrup added back. Often this form of distillers grain is pelleted for ease of handling when being utilized as a supplement. The nutritional values of this final ethanol co-product are variable between plants depending on the process and efficiency at each step. Best practices for feeding would include periodic analysis of nutrient composition, mycotoxin evaluation, and obtaining feed from the same plant consistently for a less variable product.

Wet Milling Processing Plant Ethanol Co-Products

Corn Gluten Feed

After steeping and grinding, the steeping water is evaporated and the fibrous portion of the corn kernel is added back. The product can be wet or dry depending on feed handling and long term storage needs of the feeder. The fiber in corn gluten feed is also highly digestible, thereby providing alot of energy to the ruminant animal.

Corn Germ Meal

This feed product is valuable as an ingredient in swine and poultry diets. The amino acid profile is limited by lysine because it is a product derived from corn. As the fat is removed, the corn germ meal is high in protein and fiber, but not fat.

Corn Oil

Similar to the removal of the fat from distillers grains in the dry milling process, removal of the fat increases the proportion of protein and fiber in the corn germ meal. The flow-ability and handling of deoiled corn germ meal and distillers grains also improves after removal of the fat.

Corn Gluten Meal

Corn gluten meal is a uniquely valuable ethanol co-product. The protein is highly concentrated at approximately 60% on a dry basis. It also has a low fiber content, contrary to other ethanol by-products. It is especially valuable in a poultry diet due to the high levels of xanthophylls, which are desired to naturally give the egg yolk it’s yellow pigmentation.

Professionals in the ethanol industry understand they produce imperfect animal feeds. Therefore, they work to improve technology and technique to divide those feeds to be marketed to the most appropriate species as possible. The removal of corn oil from distillers co-products resulted from livestock industry feed back. Interference of fat with rumen metabolism required low inclusion rates in the beef diet. Full fat DDGS had a negative impact on milk quality in the dairy industry. Swine fed co-products with full oil content resulted in soft bacon. The ethanol industry responded with deoiling processing. The next steps in the industry is to separate the digestible fiber portion of the co-products from the protein. Ruminants fed DDGS at a high inclusion rate are exceeding their protein requirements and therefore excreting excess N. Whereas poultry continue to have low inclusion rates of ethanol co-products in their diets due to the high fiber content. Fractionation and marketing to meet the correct livestock species needs will further improve the efficient use of these co-products as animal feeds.

As technology progresses and the nutritional profiles of ethanol co-products continues to change, feed analysis at Ward Laboratories, INC. will continue to be an important step in formulating balanced diets for livestock. When feeding “waste” or a by-product, it is important to analyze the feed routinely and procure the feed from the same plant whenever possible to reduce variability and diet adjustments needed.

this blog giving more information like a vet and very good content producing in animal segment. thanks for providing nice content.

Thank you for the positive feedback. We appreciate your reading this blog article.

Kudos to the author for unraveling the potential of ethanol co-products in enhancing both energy and agriculture sectors!